Serve-drink

Team : Mathamrai

Member

Ms Supatcha Nualthongkaew

Mr วลัญช์ เขียวขอม

Mr วีรภัทร คำภิโร

Components

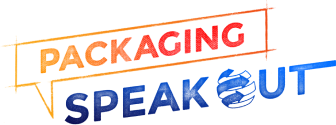

The lid consists of 2 parts attached together. Part 1 is the lower part that is attached to the water channel that allows water to pass through. Part 2 is the upper part that controls the opening and closing of the channel that allows water to pass through. It can be rotated. There are 3 channels that water can pass through. There is a grid for placing the drink sheet, which works similar to a tea bag but is an edible film in the form of a sachet containing medicine, vitamins, or powdered nutrients that can dissolve quickly in water and can be placed on the grid without falling down. There is 1 channel that water cannot pass through. If we turn the closed channel of part 2 to align with the channel of part 1, it means that it is closed and water cannot flow through. There will be a symbol indicating the location of the water flow channel.

Method

: Put the sachet containing medicine, vitamins or supplements on the grid in various compartments. When you want to eat, turn the lid to match the symbol with the compartment of the type of product you want to drink and lift it to drink. The water will pass through the product sachet and dissolve into water that gives the taste or properties of that product. The working principle is similar to the flavor changing straw but does not use additional plastic. There is no waste and it can be used with a variety of products because food, medicine, vitamins and supplements are produced in a variety of powder forms such as collagen, baby food, vitamin powder, protein powder, including sweet water, milk, various flavors.

3R

reduce - reduce the use of multiple plastics and change to a portable form, both powder products and water bottles.

reuse - reuse Our water bottles can be reused until they are worn out, not single-use bottles. The lid can be changed to suit new products while still using the same water bottle, such as increasing the number of product slots to have more options for drinking other products or flavors.

recycle - reusable by decomposing the original material. Because the bottle is made from PLA, it is easily decomposed, and the non-slip handle is made from rubber. All materials can be reintroduced into the production process.

Packaging for a brighter tomorrow:

Future product development can be applied to other products that are consumed with water without having to buy separate bottles of water, greatly reducing plastic usage, increasing the number of product compartments, and developing designs for people with color blindness, which is a problem for eating, by defining the characteristics of the cap as a universal symbol for indicating the characteristics of the product inside for consumption, including people with weak wrists, by designing the water bottle to fit the shape of the hand better, compact, and not heavy, and not causing wrist injury.

Practicality and Marketability

Server drink bottle production has industrial feasibility because it reduces the number of water bottles used, including the production of plastic water bottles with various flavors. In the future, it is possible to produce only the form of a cap + product bag with various flavors, medicines or supplements, and then assemble it with any type of water bottle for easy reuse and application to all types of bottles. The target group is diverse, such as the elderly who use powdered medicine, exercisers who use supplements, and protein powder, including children and adults who need to take vitamins. Therefore, production is worthwhile for a variety of target groups.

Marketing and brand development activities through packaging

Marketing activities by advertising in areas of potential product users, such as fitness centers or beverage shops, cafes that want to create novelty or identity for their stores by adding gimmicks to the packaging, including advertising on popular platforms, making short videos to increase access to packaging, brand development through packaging by changing the color, appearance to be more modern, or adding a function as a temperature-retaining glass to suit use in Thailand, including product development that must be used in conjunction with water bottles that cover more types of drinking water.

Business Environmental Analysis Business environmental analysis

Evaluate both internal and external business environments all the time, such as what environmental materials are currently used, we will change accordingly. These analyses are therefore important in order to be able to adapt all the time. In the future, if there are materials that can withstand heat and are biodegradable, they will be considered for use in packaging. The goal of brand development is to focus on making the brand different and easily remembered, at an accessible price, with constant changes to the functions, and the main goal is to be environmentally friendly. Multiple target groups have been identified as a sales strategy for all ages and genders, and to create recognition through online platforms.

Insight of the target group Our target group is of all ages. It helps facilitate the preparation of medicines or products packaged in water-soluble films or sachets, such as proteins, dietary supplements, to be more convenient and easy to open and hold.

Packaging design for the society and environment of the brand and the products offered. Our products are made from biodegradable plastic, environmentally friendly, reusable, suitable for all ages.